Copyright

©The Author(s) 2021.

World J Orthop. Jun 18, 2021; 12(6): 376-385

Published online Jun 18, 2021. doi: 10.5312/wjo.v12.i6.376

Published online Jun 18, 2021. doi: 10.5312/wjo.v12.i6.376

Figure 1 Layer-by-layer additive manufacturing was used to produce a monoblock cup with an ultraporous surface (Ti-Por, Adler Ortho).

Courtesy of Adler Ortho.

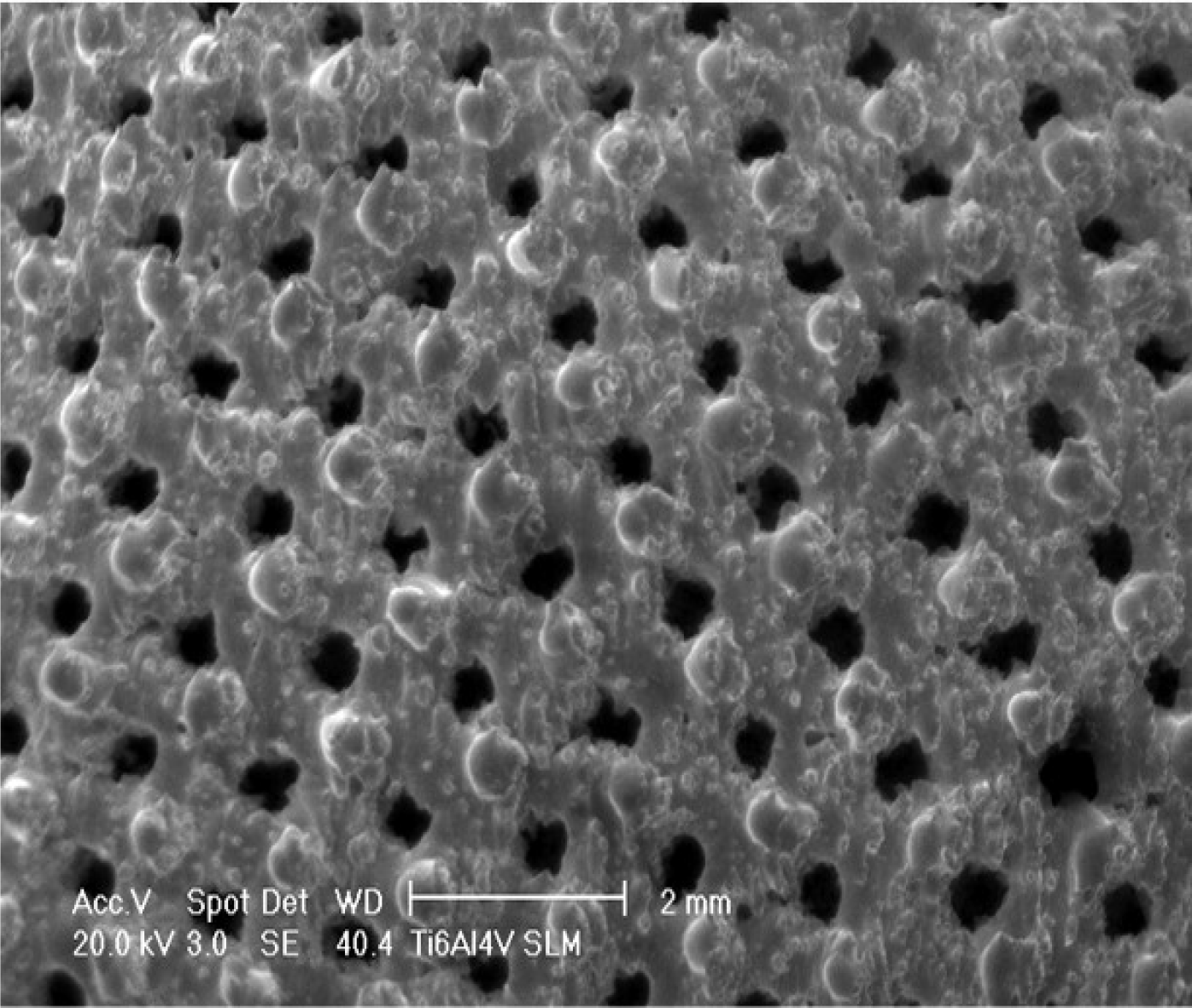

Figure 2 The highly porous surface structure has a large number of deep, interconnected pores (Ti-Por, Adler Ortho).

Courtesy of Adler Ortho.

Figure 3 A Ti-Por cup was implanted in a 59-year-old woman with primary osteoarthritis The socket has an hemispheric design with a rough surface with multiple spikes.

A: Primary osteoarthritis; B: The socket has a hemispherical design.

Figure 4 A bilateral total hip arthroplasty, with a Ti-Por cup on the right and a hydroxyapatite-coated socket on the left.

The different surface roughness is evident. Both the cups had good radiographic osseointegration at 3 years.

- Citation: Castagnini F, Caternicchia F, Biondi F, Masetti C, Faldini C, Traina F. Off-the-shelf 3D printed titanium cups in primary total hip arthroplasty. World J Orthop 2021; 12(6): 376-385

- URL: https://www.wjgnet.com/2218-5836/full/v12/i6/376.htm

- DOI: https://dx.doi.org/10.5312/wjo.v12.i6.376