Copyright

©The Author(s) 2015.

World J Orthop. Oct 18, 2015; 6(9): 705-711

Published online Oct 18, 2015. doi: 10.5312/wjo.v6.i9.705

Published online Oct 18, 2015. doi: 10.5312/wjo.v6.i9.705

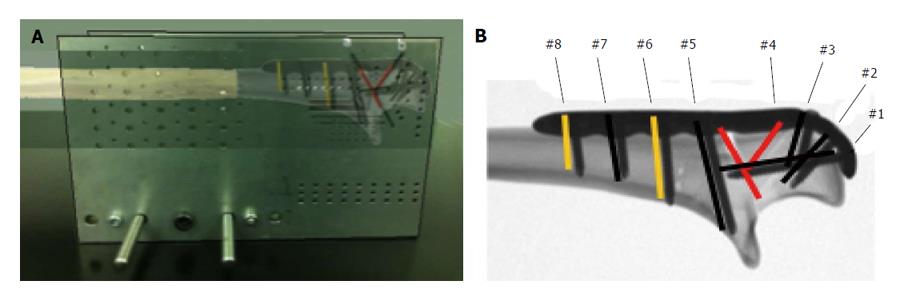

Figure 1 Custom osteotomy jig with plate and screw construct.

A: Rendered photo of the jig used to create the comminuted olecranon fracture, with an overlay of the ulna, demonstrating the positioning of the bone in relation to the saw blade slots; B: A radiograph of the olecranon plate and screw construct in relation to the fracture. Screws placed in positions as indicated in Table 1.

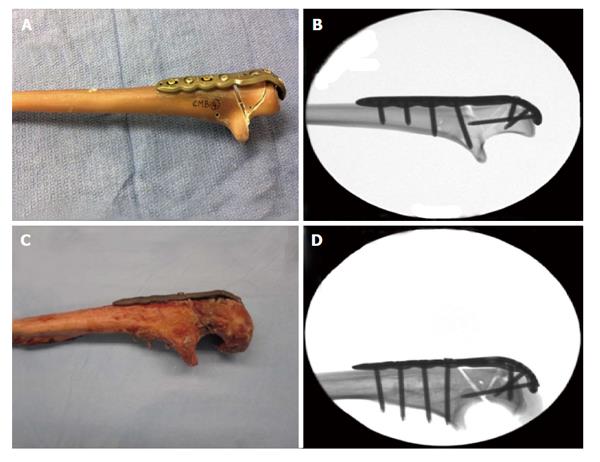

Figure 2 Fourth generation composite bone (A) and human cadaveric bone (C) with a comminuted olecranon fracture, fixed with a pre-contoured plate and screw construct, and lateral fluoroscopic radiographs of the composite bones (B) and human cadaveric ulna (D).

The fracture is fixed with the olecranon plate and fixation screw.

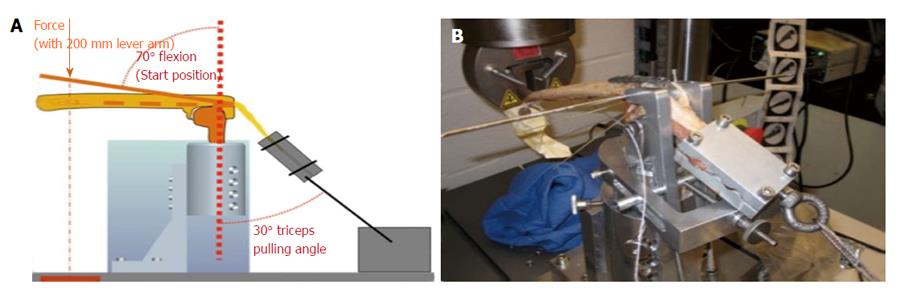

Figure 3 Custom mounting device.

A: Pictorial representation of the test apparatus, demonstrating the ulna mounted on a potted distal humeral mould. The force was applied at 200 mm from the joint, and the triceps is clamped and retracted at a 30 degree angle; B: Photograph of the experimental setup, which includes the differential variable resistance transducer placed across the fracture site to measure fracture motion.

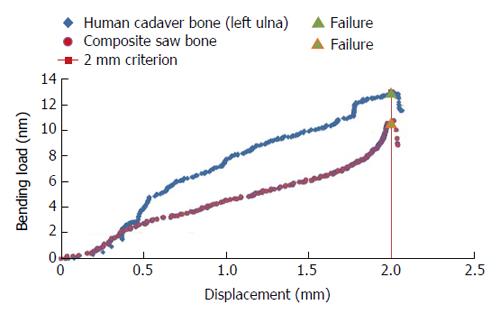

Figure 4 Sample graphs showing the force-displacement curve during destructive loading for composite bone and human cadaver bone specimens.

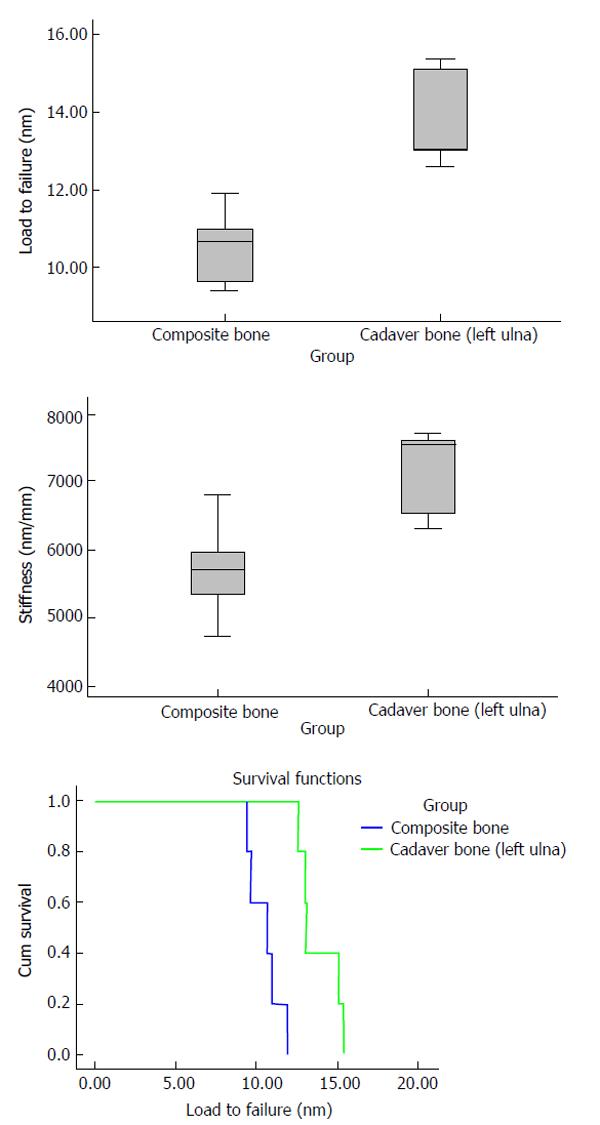

Figure 5 Load to failure criterion of 2 mm gapping, stiffness per specimen and survival function of specimens.

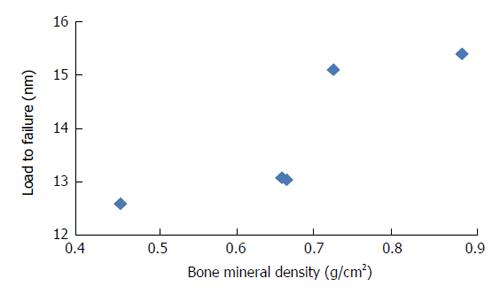

Figure 6 Bone mineral density in human cadaver bones (left ulnas), n = 5.

- Citation: Hamilton Jr DA, Reilly D, Wipf F, Kamineni S. Comminuted olecranon fracture fixation with pre-contoured plate: Comparison of composite and cadaver bones. World J Orthop 2015; 6(9): 705-711

- URL: https://www.wjgnet.com/2218-5836/full/v6/i9/705.htm

- DOI: https://dx.doi.org/10.5312/wjo.v6.i9.705