Copyright

©The Author(s) 2025.

World J Stem Cells. Aug 26, 2025; 17(8): 107124

Published online Aug 26, 2025. doi: 10.4252/wjsc.v17.i8.107124

Published online Aug 26, 2025. doi: 10.4252/wjsc.v17.i8.107124

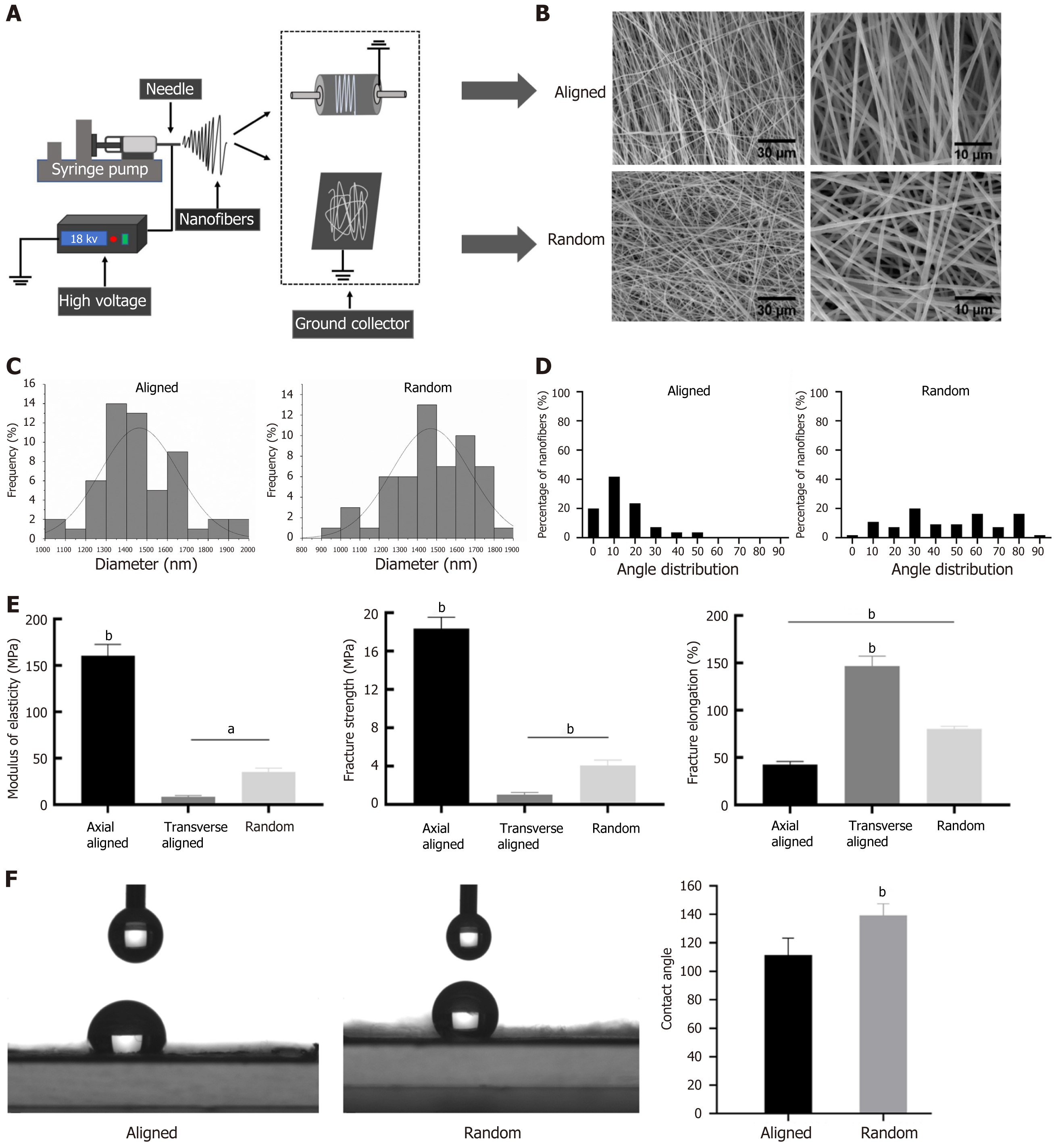

Figure 1 Preparation and performance testing of random and aligned nanofiber scaffolds.

A: Schematic of the electrospinning setup used for fabricating random and aligned nanofiber scaffolds, utilizing a rotating collector for aligned fibers and a stationary collector for random fibers; B: Scanning electron microscopy images showing the morphology of aligned (top) and random (bottom) nanofiber scaffolds, with aligned fibers displaying a parallel structure and random fibers exhibiting a disordered configuration. Scale bars: 30 μm and 10 μm; C: Diameter distribution of fibers in both types of scaffolds, showing consistent diameters; D: Angle distribution of fibers, with aligned fibers having a narrow angular dispersion, confirming uniform orientation, while random fibers display a broader angle range; E: Mechanical properties measured as modulus of elasticity, fracture strength, and fracture elongation, with aligned scaffolds showing higher values compared to transverse aligned and random scaffolds; F: Contact angle measurements showing differences in surface wettability, with random fibers having a higher contact angle, indicative of greater hydrophobicity. aP < 0.05, bP < 0.01.

- Citation: Yang CW, Zhang YQ, Chang H, Gao R, Chen D, Yao H. Aligned nanofiber scaffolds combined with cyclic stretch facilitate mesenchymal stem cell differentiation for ligament engineering. World J Stem Cells 2025; 17(8): 107124

- URL: https://www.wjgnet.com/1948-0210/full/v17/i8/107124.htm

- DOI: https://dx.doi.org/10.4252/wjsc.v17.i8.107124